Welding Tools

- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

Equip your workshop with essential welding tools from ArcCaptain. From must-have hand tools to precision accessories, our collection is curated to support every step of your MIG, TIG, and Stick welding projects, helping you achieve professional results with greater efficiency and safety.

Features & Benefits of Welding Tools From ArcCaptain

At ArcCaptain, we pride ourselves on offering a range of welding tools designed to meet the diverse needs of welders. Whether you’re a seasoned expert or just starting, our tools provide reliability, efficiency, and safety, allowing you to work more efficiently. Explore the benefits that come with choosing our products.

-

Durable Construction: Our tools are built to withstand the rigors of welding environments, ensuring longevity and reliability.

-

Enhanced Performance: Experience improved welding quality with tools that are engineered for optimal performance and precision.

- User-Friendly Design: We focus on creating tools that are easy to use, making your welding tasks smoother and more enjoyable.

Essential Welding Accessories for Every Welder

The foundation of any welding project starts with the right hand tools. ArcCaptain provides durable, purpose-built tools to prepare, assemble, and finish your work.

Optimize Your Workspace With Quality Tools

An organized workspace can significantly improve your efficiency. Welding magnets play a crucial role in keeping the workspace organized and stable by holding workpieces at specific angles.

Tools like the TIG torch holder help keep your area tidy and ensure that your equipment is always within reach. This minimizes distractions and allows you to concentrate on your welding projects.

Versatile Options for Every Welding Task

Our collection includes a variety of welding tools tailored for different applications. These tools are available in various sizes to suit different welding tasks. Whether you’re working with aluminum or need specific gasless MIG welding wire, we have the right tools for the job.

Explore our aluminum welders collection to find specialized equipment designed for optimal performance.

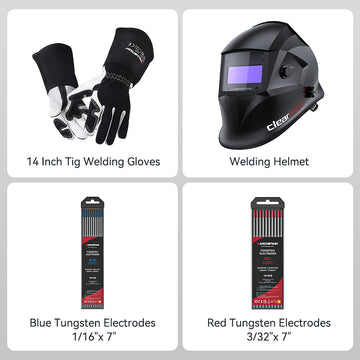

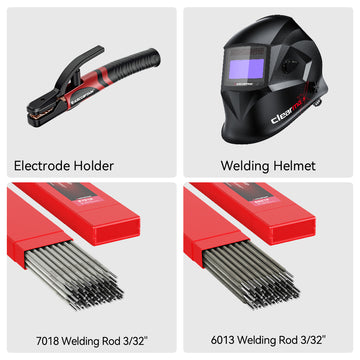

Welding Safety Gear & Protection

Safety is the first rule of welding. Protect yourself with ArcCaptain's reliable personal protective equipment (PPE).

- Auto-Darkening Welding Helmets: Protect your eyes and face from arcs and spatter with variable shade lenses.

- Welding Gloves & Jackets: Heat-resistant leather gloves and flame-retardant clothing to shield against sparks and UV radiation.

- Respirators: Protect your lungs from harmful welding fumes and particulate matter generated during the process.

Protective gear, such as welding aprons, shields, and helmets, is essential for safeguarding against sparks and heat. Investing in welding gear not only protects you but also enhances your focus on the task at hand.

Workshop Organization & Support

Stay organized and efficient with tools designed to optimize your workspace.

- TIG Torch Holders & Ground Clamp Holders: Keep your hot torch and ground clamp secure and off your workbench.

- Cable Management: Protect your welding cables and keep your area tidy to prevent tripping hazards.

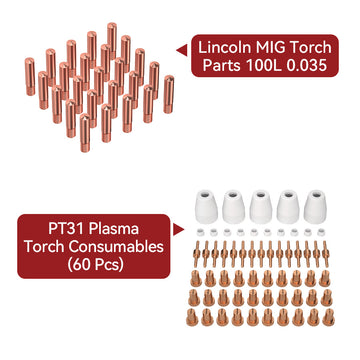

Welding Consumables & Supplies

Maintain your equipment and ensure consistent weld quality with ArcCaptain consumables.

- MIG Gun Consumables: Nozzles, contact tips, and diffusers for maintaining your MIG welding gun.

- Tungsten Electrodes: For TIG welding various metals, including 2% Lanthanated for AC/DC applications.

- Filler Metals: MIG welding wire and TIG welding rods in various alloys.

Factors To Consider When Choosing Welding Tools

When selecting welding tools, it’s essential to consider several key factors to ensure you make the best choice for your projects:

It is also important to consider the material thickness when selecting welding tools, as this can significantly impact the quality and effectiveness of your welding work.

Type of Welding

Different welding techniques require specific tools to achieve optimal results. For instance, MIG welding tools are designed for fast and efficient work on thicker materials, while TIG welding tools offer precision for thinner metals and intricate designs.

Stick welding tools are versatile and great for outdoor projects. Understanding the type of welding you plan to do will help you choose the right equipment. Brazing is another important metalworking process, often used in welding applications and maintenance, which requires clean equipment, like torch tips, for effective results.

Material Compatibility

Not all welding tools are suitable for every material. It’s crucial to ensure that the tools you select are compatible with the materials you intend to work with, whether it’s steel, aluminum, or other metals. Using the right tools for cutting different materials is also essential to achieve precise and clean results.

Using the wrong tools can lead to poor weld quality and may even damage the materials. Always check the specifications of your tools to confirm they align with your project requirements.

Durability and Build Quality

Welding can be a demanding process, so it’s important to choose tools made from high-quality materials that can withstand heat, spatter, and the physical stresses of welding. Look for tools that are built to last, with robust construction and reliable components.

Investing in durable tools not only enhances performance but also reduces the need for frequent replacements, saving you time and money in the long run.

Ease of Use

Consider how user-friendly the tools are, especially if you are a beginner. Tools that are intuitive and easy to handle can significantly improve your welding experience. Features like ergonomic designs, adjustable settings, and clear instructions can make a big difference in your comfort and efficiency while working.

Safety Features

Safety should always be a priority when welding. Look for tools that come with built-in safety features, such as protective guards, safety switches, and high-temperature resistance. Ensuring your tools have these features can help prevent accidents and injuries in the workshop.

Convenience and Portability

Convenience and portability are key factors that can significantly enhance your productivity. At ArcCaptain, we offer a range of portable welding equipment designed to make your work easier, whether you’re on-site or in a remote location.

Frequently Asked Questions on Welding Tools

Why is it important to know the different welding tools and equipment?

Understanding the function of each welding tool is critical for safety, efficiency, and weld quality. Using the correct tool, like a chipping hammer for slag or clamps for alignment, ensures strong joints and prevents accidents. This knowledge also allows for proper equipment maintenance and troubleshooting common issues.

What tools are necessary for welding?

The necessary tools extend beyond the welding machine itself. Essential tools include an auto-darkening helmet, welding gloves, and a jacket for safety. You also need clamps to hold material, a wire brush for cleaning, welding pliers for maintenance, and a grinder for prep and finishing. The exact tools can vary by process.

How do you maintain welding tools and equipment?

Maintenance is key for longevity and safety. Clean tools regularly to remove spatter and debris. Inspect cables for damage and replace worn consumables like MIG contact tips and TIG cups. Lubricate moving parts on clamps and store equipment in a clean, dry place to prevent rust and damage.

What should I consider when choosing welding tools?

Consider the welding process (MIG, TIG, Stick) and materials you'll be working with. Prioritize durability—tools should withstand heat and physical abuse. Safety features, ergonomic design for comfort, and portability for on-the-go jobs are also crucial factors for selecting the right equipment.

Is a grinder an essential welding tool?

Yes, a grinder is one of the most important tools in a welder's shop. It is used for beveling edges, removing rust, cleaning surfaces before welding, and grinding down welds for a smooth finish. An angle grinder with both grinding and cutting wheels is incredibly versatile for metal fabrication.

Should a beginner use a MIG or ARC welder?

For most beginners, a MIG welder is the recommended starting point. The MIG process (also called Wire-Welding) is easier to learn as it uses a wire feed system that acts as both the electrode and filler metal, making it simpler to control and create consistent welds.

An ARC (Stick) welder, while versatile and portable, has a steeper learning curve as it requires more skill to strike and maintain a stable arc, making it more challenging for a novice to achieve clean results.