Lack of fusion in welding weakens joints and can cause failures. This problem happens when the weld doesn't properly merge with the base metal, leaving a weak spot. It can be due to bad weld setup, wrong welding methods, or not enough heat.

To avoid this, make sure the metal edges are clean and shaped right before you start. Use the right welding method for your metal and adjust the heat to get a good weld. Also, choose the right settings and gas to keep the weld clean and strong.

If you spot a bad weld, fix it quickly by re-welding the bad part or checking the weld's strength with special tests.

Keep reading to learn how to spot and fix welding issues like lack of fusion, making your welds stronger and safer.

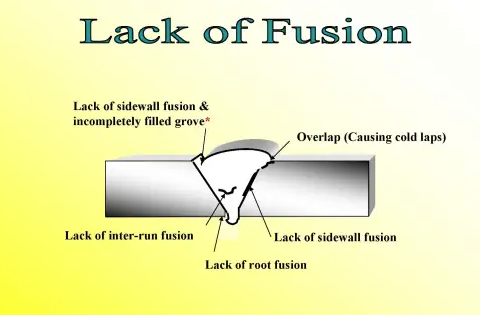

What is Lack of Fusion in Welding?

Image Source @ https://pinoywelders.wordpress.com/2014/06/16/lack-of-fusion/

Lack of fusion is a welding defect that can occur when the weld does not properly fuse with the base metal. This defect can lead to weak and unreliable joints that are more likely to fail under stress and pressure. When welding two pieces of metal together, it is important to ensure the weld is strong and secure.

Lack of fusion can occur for a variety of reasons, including:

- improper welding techniques

- incorrect torch angle

- incorrect electrode type

- poor weld preparation

- inadequate shielding gas.

It is important to identify and address the root cause of the defect to prevent further issues.

Lack of Fusion Vs. Other Welding Defects

Lack of fusion is different from other welding defects such as porosity, cracks, and lack of penetration. Porosity occurs when gas is trapped in the weld, while cracks occur when the metal cools too quickly. Lack of penetration occurs when the weld does not penetrate deep enough into the base metal.

To avoid a lack of fusion, it is important to use proper welding techniques, select the correct electrode type, maintain proper torch angle and travel speed, and ensure adequate shielding gas coverage. Proper preparation of the base metal is also crucial to ensure a strong and secure weld.

Causes of Lack of Fusion

Several factors can contribute to the formation of a lack of fusion in welds.

Some of these factors include:

- Insufficient heat input: When the heat input is too low, the weld metal may not melt sufficiently to bond with the base metal, resulting in lack of fusion.

- Inadequate welding technique: Welding techniques such as incorrect torch angle, incorrect electrode type, and improper travel speed can all cause lack of fusion.

- Poor preparation: If the base metal is not properly cleaned or prepared before welding, impurities such as rust or oil can prevent the weld metal from bonding with the base metal.

- Large gaps in the weld joint: Large gaps in the weld joint can prevent direct arcing to the base metal weld surface, resulting in a lack of fusion.

Identifying Lack of Fusion

It is essential to identify lack of fusion in welds to prevent welding defects and imperfections.

Some of the ways to detect lack of fusion include:

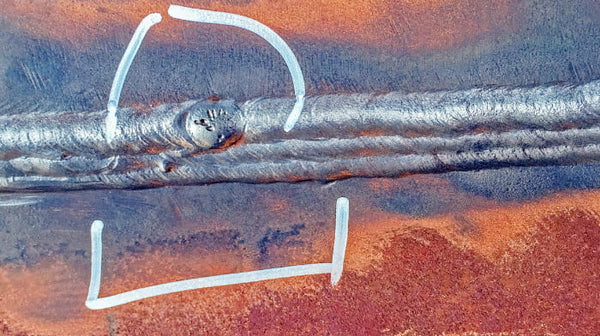

- Visual inspection: A visual inspection of the weld can help detect lack of fusion. Lack of fusion can appear as a crack or gap between the weld metal and the base metal.

- Ultrasonic testing: Ultrasonic testing can detect lack of fusion by sending high-frequency sound waves through the weld and measuring the time it takes for them to bounce back.

- Radiographic testing: Radiographic testing can detect lack of fusion by taking an x-ray or gamma-ray image of the weld and analyzing it for any discontinuities.

Lack of Fusion: Effects on Weld Quality

Lack of fusion can have several effects on weld quality, including:

- Reduced strength: Lack of fusion can result in weak welds that are more likely to fail under stress and pressure.

- Porosity: Lack of fusion can lead to porosity, which are small holes or voids in the weld metal that can weaken the weld.

- Cracks: Lack of fusion can also lead to cracks in the weld, which can compromise its structural integrity.

Read Related Articles:

- What is Porosity in Welding: Common Causes and Prevention

- What is Slag in Welding: Causes, Types, and Prevention Strategies

How to Prevent Lack of Fusion in Your Welding Projects?

To prevent this from happening in your welding projects, it is important to follow best practices for welding techniques and parameters.

Here are some tips to help you prevent lack of fusion in your welding projects:

1. Choose the Right Materials and Equipment

Choosing the right materials and equipment is critical to preventing lack of fusion. Make sure that the materials you are welding are compatible and that you have the appropriate equipment for the job. Using the wrong equipment or materials can result in a lack of fusion.

2. Use Proper Welding Techniques

Using proper welding techniques is essential to achieving a strong weld. Make sure that you are using the correct welding technique for the materials you are working with. For example, TIG welding may be more appropriate for certain materials than MIG welding.

3. Control Welding Parameters

Controlling welding parameters is also important to preventing lack of fusion. Make sure that you are using the correct settings for your equipment and that you are monitoring the heat input. Too much or too little heat can result in a lack of fusion.

4. Prepare the Weld Joint Properly

Proper preparation of the weld joint is critical to achieving a strong weld. Make sure that the joint is clean and free of any contaminants that could interfere with the welding process. Use a wire brush or grinder to clean the joint and remove any rust or debris.

Conclusion

In conclusion, lack of fusion in welding is a critical issue that must be addressed to ensure quality and safety. As we have seen, a lack of fusion can lead to weak welds that are more likely to fail under stress and pressure. The molten metal must mix and bond with the base metal to create a viable bond.

To promote proper fusion, it is important to control factors such as the welding technique, parameters, heat input, and proper preparation. Ensuring that the welding process parameters, such as heat input, travel speed, and electrode selection, are optimized for the specific materials being welded can promote adequate fusion. Rust or other impurities in the base metal can also be a source of lack of fusion.

Preventive measures can help minimize the occurrence of lack of fusion. Proper preparation of the joint, including cleaning and removing any impurities, is critical. Additionally, selecting the appropriate welding technique and parameters can help ensure proper fusion.

Prevent Lack of Fusion with arcCaptain's High-Quality Welding Machines

To prevent lack of fusion—a common yet avoidable flaw in welding—it's essential to choose the right tools. arcCaptain's high-quality welding machines, like the:

- ARCCAPTAIN MIG200 Multi Process MIG Welder

- ARCCAPTAIN TIG200P AC DC Multi Process Pulse TIG Aluminum Welder

They are designed to tackle this issue head-on. The MIG200 is versatile,and perfect for a variety of materials, ensuring deep penetration and strong bonds. The TIG200P excels with aluminum, offering precise control for a flawless fusion.

Explore these top products and more to ensure your welding projects are successful and durable. Learn more at ArcCaptain.

Frequently Asked Questions

What is Lack of Fusion in Spot Welding?

Lack of fusion in spot welding occurs when the metal components are not properly bonded together. This can happen due to insufficient heat input, inadequate joint preparation, or poor welding technique. Spot welding is a process that involves applying heat and pressure to two metal components that are held together, causing them to melt and fuse. If the heat is not sufficient or the components are not properly prepared, the weld may not fully fuse, leading to a lack of fusion.

What is Lack of Fusion in Fcaw Welding?

Lack of fusion in FCAW (Flux Cored Arc Welding) occurs when the weld metal does not fully fuse with the base metal. This can happen due to several factors, including improper welding technique, incorrect heat settings, or insufficient penetration of the weld into the base metal. FCAW is a welding process that uses a flux-cored wire to shield the weld pool from the atmosphere. If the wire is not properly fed or if the heat input is not sufficient, the weld may not fully fuse, leading to a lack of fusion.

What is Lack of Fusion in Aluminum Welding?

Lack of fusion in aluminum welding occurs when the weld metal does not fully fuse with the base metal. This can happen due to several factors, including improper welding technique, incorrect heat settings, or insufficient penetration of the weld into the base metal. Aluminum welding requires a high heat input and proper preparation to ensure that the weld fully fuses with the base metal. If the heat input is not sufficient or the preparation is inadequate, the weld may not fully fuse, leading to a lack of fusion.

What is the Difference Between Lack of Fusion and Cold Lap?

Lack of fusion and cold lap are both welding defects, but they occur for different reasons. Lack of fusion occurs when the weld metal does not fully fuse with the base metal, while cold lap occurs when the weld metal does not properly fuse with itself. Cold lap can happen when the heat input is too low or the welding technique is incorrect, causing the weld metal to solidify before it has fully fused with the adjacent weld metal. Lack of fusion, on the other hand, can happen due to several factors, including insufficient heat input, inadequate joint preparation, or poor welding technique.

What Are the Two Types of Fusion Welding?

The two types of fusion welding are gas welding and arc welding. Gas welding involves heating the metal components with a flame and then fusing them, while arc welding involves using an electric arc to heat the metal components and then fusing them. Both types of welding require proper preparation and technique to ensure that the weld fully fuses with the base metal.

What is Fusion Welding?

Fusion welding is a welding process that involves melting the metal components and then fusing them. This can be done using a variety of techniques, including gas welding, arc welding, and resistance welding. Fusion welding requires proper preparation, technique, and heat input to ensure that the weld fully fuses with the base metal. Lack of fusion is a common defect in fusion welding and can happen due to several factors, including insufficient heat input, inadequate joint preparation, or poor welding technique.