Introduction

MIG welding is one of the common welding processes which are used on large scale in automotive factories, workshops concerned with steel structures fabrication and sheet metal works due to its high productivity and good weld quality. Arc stuttering happens with MIG welding and is defined as the construction of unstable arc at the start of arc and result in improper spatter of arc. In this blog, we will know more about how this issue happens and how to avoid it.

What is arc stuttering and how does it happen?

Arc stuttering is the construction of unstable arc at the beginning of MIG welding while the arc is being struck and this issue appear as intermittent arc flashes. Arc stuttering occurs due to wire feed issues like holding too long of a standoff as the arc is being struck, so when arc struck, the wire will try to burn back to accommodate the arc length that match with the established welding voltage and arc will start to stutter and pop in the form of intermittent arc flashes. The long wire standoff happens when you are trying to lift the nozzle too high to see the weld puddle during welding and also may happen due to higher wire feed speed which will tend to get longer wire standoff.

Also, this issue can happen when you are not tightly holding the welding gun at the start of welding, so when the arc struck, the gun will go back which result in long standoff distance and consequently, the wire will burn in inconsistent way causing stuttering arc and this usually happens with beginners by holding too loose of a grip and allowing the force of the wire to “push back” the nozzle back when it first strikes the metal. Stuttering arc can happen due to misfire of the arc when you by mistake strike an arc and this usually happens with beginners.

What is the result of having stuttering arc?

The burn back of wire in inconsistent way due to stuttering leads to the deterioration of connection tip and nozzle, so you have to cut the wire tip and clean the connection tip before starting welding again. Also, the stuttering arc causes unwanted spatter at the arc crater, so when this happens, you have to grind the weld crater and clean it properly before starting welding again.

How to avoid arc stuttering?

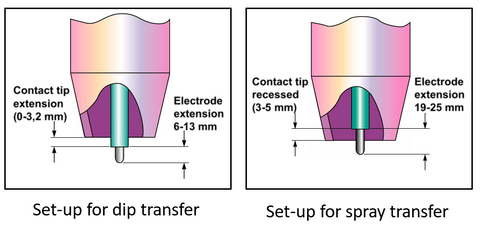

First, you have to keep proper standoff distance of wire as shown to keep 6-13 mm wire extension for dip transfer and 19-25 mm for spray transfer.

Second, you have to grasp the welding gun firmly and if needed support your arm and gently start with the gun trigger and try to hold the gun not to go back at starting the arc. If the gun started to push back, push it forward and firmly hold the welding gun.

Third, do not keep long distance between the contact tip and weld as in this case, the arc will not be established with starting the gun trigger as it will need higher voltage more than the one you are using, so in this case the wire will continue to go out of the tip toward the weld without arcing and when the distance becomes suitable with the established voltage, the arc will start and there will be inconsistent burning of wire.

About the author

Benjamin Mina is from Egypt, He had bachelor degree of science BSc in materials and metallurgical engineering since 2007 from Suez canal university in Egypt and He had an international welding engineer certification IWE since 2009 as a partnership between the central metallurgical research and development institute - Egypt (IIW - Approved Training Body) and SZA-SchweiBtechnische Zentralanstalt - Austria (IIW - Authorized National Body) and recently he got the master degree of science in metallurgical engineering MSc from Cairo university. He have long experience in welding and materials engineering which is gained as per my work as welding engineer and non-destructive testing specialist in the construction field in constructing new oil and gas, refinery and power station projects in addition to shutdowns and maintenance work for running oil plants and pipelines.