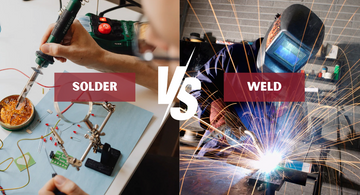

Understanding solder vs weld is important when joining metal. Soldering uses low heat and filler metal, making it perfect for electronics and delicate projects.

Welding, on the other hand, melts the metals together using high heat, creating a much stronger bond for construction and industrial work.

The right method depends on your materials, strength requirements, and project type. In this article, we’ll break down each technique's key differences, pros, and best uses.

If you're looking for a high-quality welding machine, ArcCaptain offers some of the best options on the market. Keep reading to learn more

What Is Soldering?

Soldering is a method for joining metals using a filler metal known as solder. This process is characterized by the following:

- Process: The solder has a melting point below that of the base materials. When heated, it melts and flows into the joint, creating a solid bond upon cooling.

- Heat Source: You typically use soldering irons or guns to heat the solder to its melting point without affecting the base materials.

- Applications: This technique is widely used in electronics for connecting wires and components, in plumbing for sealing pipes, and in jewelry making.

Benefits of Soldering

- Low Heat Requirements: The lower melting point means you require less heat, reducing energy consumption and simplifying the setup.

- Minimal Damage: Because you use less heat, there's less risk of damaging sensitive or small parts of the materials being joined.

- Precision: Soldering provides the ability to work on small and delicate projects with high precision.

These features make soldering an attractive choice for many applications where careful and reliable assembly is needed.

What Is Welding?

Welding is a process where you fuse materials by melting the base metals. You often add a filler material to create a strong bond. This technique uses a high heat source, which can be generated through gas, electricity, or even lasers.

When you weld, you are creating a permanent connection that is incredibly strong. This makes welding a great choice for projects that need durability and strength, such as construction or automotive repair.

Welding is highly versatile and works well with a wide range of metals and materials. Whether you are building a bridge or repairing heavy machinery, welding can meet your project needs.

Here are some benefits of welding:

- Strong Bond: Welding provides a strong and permanent connection between materials.

- Versatile Applications: It is ideal for heavy-duty settings like construction and automotive repair.

- Material Compatibility: You can use welding on various metals and materials.

Whether you are using it for industrial purposes or in a smaller workshop, welding is a reliable method to produce sturdy, long-lasting joins.

Solder vs Weld: Key Differences

Heat Requirements

Soldering uses low heat, around 400°F. This makes it perfect for working with sensitive materials that can't withstand high temperatures.

In contrast, welding requires extremely high heat, often reaching thousands of degrees, to melt the base materials and create a strong fusion.

Strength of the Joint

When you solder, the joints created are weaker and best suited for light-duty tasks, like electrical connections.

Welding, however, creates strong and durable joints. These are ideal for structural applications where strength is essential.

Materials Used

Soldering is commonly used with thin metals, wires, and electronics. It allows you to work on delicate components without damaging them.

Welding is better for thick materials such as steel, aluminum, and iron, where a strong bond is needed.

Skill Level

Soldering is more beginner-friendly, requiring less training to get started. It’s a great skill if you want to work on simple tasks with minimal risk.

Welding, on the other hand, demands more expertise and safety precautions. It often requires formal training to master.

Equipment Costs

Soldering tools are generally inexpensive and portable. This makes it easy to set up a work station without a large investment.

Welding equipment is more costly and involves additional safety gear, such as helmets and gloves, to protect against high heat and sparks.

When to Choose Soldering vs Welding?

Soldering is best for electronics and intricate work. When you're dealing with circuit boards or electronics, soldering is the way to go. It uses lower temperatures, which is crucial to avoid damaging sensitive components.

Another good choice for soldering is jewelry repair, where precision is key. It's also effective for sealing small plumbing pipes where minimal heat is required.

Welding is more suitable for heavy-duty projects. If you are working on automotive or construction projects, welding provides the strength needed to handle stress and load.

It's perfect for fabricating or repairing structures made of thick metals.

For instance, welding is commonly used when joining large metal surfaces like girders or vehicle frames.

When to Use Each Technique

|

Situation |

Technique |

|

Electronics & Circuit Boards |

Soldering |

|

Jewelry Repair |

Soldering |

|

Small Plumbing Pipes |

Soldering |

|

Automotive Projects |

Welding |

|

Construction & Heavy Structures |

Welding |

|

Thick Metals or Large Surfaces |

Welding |

Examples: When fixing an electronic gadget, soldering is precise. Constructing a steel frame? Welding fits the task. Evaluating these factors helps ensure you select the right method for your needs.

Essential Tools for Soldering and Welding

When working with metals, having the right tools is crucial. Whether you're soldering or welding, each method requires specific equipment to get the job done safely and efficiently.

Soldering Tools

- Soldering Iron or Gun: This handheld tool is essential for melting and applying solder.

- Solder Wire: Available in lead-free or lead-based varieties, this wire acts as a filler material.

- Flux: Helps clean surfaces for better adhesion by removing oxidation.

- Heat-Resistant Mat: Protects your work surface from heat damage.

Welding Tools

- Welding Machine: Choose from MIG, TIG, or stick welders, depending on your project needs.

- Filler Rods or Electrodes: These are used to join metal pieces in the welding process.

- Welding Helmet and Gloves: Critical for protecting your eyes and skin from sparks and UV radiation.

- Protective Clothing: Wear flame-resistant gear to safeguard against burns and other injuries.

Selecting the right tools enhances your precision and ensures that your work is both effective and safe.

Always prioritize safety gear and quality equipment to achieve the best results in your metalworking projects.

Also read: 🔗Safety Equipment in Welding: 8 Must-Have PPE for Welders

How to Stay Safe When Working With Heat and Metals

Staying safe while soldering or welding is essential. Follow these key precautions to protect yourself and your workspace.

Soldering Safety Tips

✅ Work in a well-ventilated area – Avoid inhaling harmful fumes.

✅ Use a heat-resistant mat – Protect your work surface from burns.

✅ Wear safety goggles & gloves – Prevent injuries from hot materials.

Welding Safety Tips

✅ Wear a welding helmet – Protect your eyes from bright light and sparks.

✅ Use flame-resistant clothing – Avoid burns from sparks and molten metal.

✅ Ensure proper ventilation – Reduce exposure to toxic welding fumes.

By following these safety measures, you can work efficiently while minimizing risks!

Here’s a quick comparison table for safety gear:

|

Task |

Protection |

Additional Gear |

|

Soldering |

Safety goggles & gloves |

Heat-resistant mat |

|

Welding |

Welding helmet |

Flame-resistant clothing |

Potential hazards include burns, exposure to toxic fumes, and injuries from sharp tools. Always stay alert and follow these safety measures to reduce risks.

Weighing the Pros and Cons: Solder vs Weld

Soldering Pros:

- Affordable Equipment: You can get started with soldering tools without spending much.

- Easy to Learn: Soldering requires less training to master than welding.

- Ideal for Small, Precise Projects: It's perfect for electronic work and detailed tasks.

Soldering Cons:

- Weak Joints: The bonds created are not as strong as welded joints.

- Limited to Low-Temperature Applications: You cannot use it for high-heat scenarios.

Welding Pros:

- Strong, Permanent Bonds: Welding provides durable and long-lasting connections.

- Versatile for Various Metals and Applications: You can weld different types of metals for many purposes.

Welding Cons:

- Expensive Equipment: Welding tools and machines can be costly to purchase and maintain.

- Requires Advanced Skills and Safety Precautions: Mastery involves training, and you must follow strict safety guidelines.

Final Thoughts

Choosing between solder vs weld depends on your project’s needs. Soldering is ideal for electronics and delicate work, while welding provides strong, durable joints for construction and heavy-duty applications.

Understanding their key differences helps you pick the right technique for the job.

If you need high-quality welding equipment, ArcCaptain has you covered!

They offer:

designed for precision, power, and durability.

Whether you’re a beginner or a pro, ArcCaptain has the perfect machine for you.

Check out ArcCaptain today and upgrade your welding setup!

Related Products:

ARCCAPTAIN TIG200P AC DC Multi Process Pulse TIG Aluminum WelderThe AC DC TIG200P is our most powerful, best-selling, and top-rated high-performance Pulse Aluminum TIG Welder, highly recognized for its exceptional performance in aluminum welding and thin plate welding projects. |

|

Arccaptain iControl CUT55 Pro Pilot Arc Plasma CutterCUT55 Pro Pilot Arc Cutter by Arccaptain is a high-end plasma cutter with an upgraded design and innovative air duct system, increasing cutting efficiency by 39%. The non-contact pilot arc design enhances cutting performance across various materials and scenarios without compromising quality. |

|

|

|

ARCCAPTAIN MIG205 Pro Multi Process MIG WelderThe MIG205 Pro features enhanced welding capabilities, localized screen language options, and improved heat dissipation for a smoother, more efficient welding experience. |

Frequently Asked Questions

When deciding between soldering and welding, you need to consider several factors, such as application needs, safety, and cost. Both methods have their unique uses and limitations.

Can soldering replace welding?

Soldering cannot always replace welding. Soldering is best for delicate work like electronics, while welding is better for heavy-duty tasks such as construction. If you need strong, durable joints, welding should be your choice. Conversely, soldering is ideal when working with materials that cannot withstand high heat.

Is soldering safer than welding?

Soldering is generally considered safer than welding. It involves lower temperatures, which reduces the risk of burns and minimizes harmful gas exposure. However, you should still use protective gear when soldering, as it can produce fumes that are harmful if inhaled.

What metals can be soldered?

You can solder metals such as copper, brass, and tin. These metals have suitable melting points and properties for the soldering process. Some other metals can also be soldered with the right techniques and materials, but it often depends on compatibility with the solder used.

Which is more expensive: soldering or welding?

Welding is typically more expensive than soldering. It requires more specialized equipment and training. The cost of materials and the energy needed are also higher for welding. In contrast, soldering usually involves simpler tools, making it more affordable for small-scale or hobby projects.

Is soldering and welding the same thing?

Soldering and welding are two different processes. Soldering uses a filler metal that melts at a lower temperature than the pieces being joined. Welding involves melting the workpieces themselves to create a strong bond, often using high heat and pressure.

What factors determine whether to use soldering, welding, or brazing in metalwork?

The choice between soldering, welding, or brazing depends on the materials and the strength of the joint required. Soldering works for low-strength, heat-sensitive applications. Welding is chosen for high-strength needs. Brazing, like soldering, uses a filler metal but at higher temperatures and can be used for more robust connections without melting the base materials.

Read Related Articles 📖