Metal Fabrication Tools

- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

Welcome to ArcCaptain's Metal Fabrication Tools collection! We’re dedicated to making metal fabrication easy and efficient, especially when it comes to welding. Whether you’re just starting out or a seasoned pro, our selection of fabrication tools is designed to support your metal fabrication process from start to finish.

Welding is one of the core methods used in metal fabrication to join metal pieces together, ensuring your projects are both strong and visually appealing. At ArcCaptain, we offer fabrication tools that are dependable, easy to use, and crafted for optimal performance. From MIG, TIG, and Stick welders to plasma cutters, we stock everything you need for a successful metal fabrication project.

Our tools are easy to use and dependable, so you can focus on creating something great. We have all kinds of welders - MIGTIG, Stick - to fit what you're doing. ArcCaptain is here to help you make cool things with metal.

Let's get started on your next project with tools that are ready to go when you are. Welcome to where metal takes shape!

Why Do Metal Fabrication Tools Matter?

Having the right metal fabrication tools can significantly improve the efficiency and quality of your work. Whether you’re cutting, welding, or shaping tubing, the right tools make all the difference. ArcCaptain provides everything you need, from welding machines to grinders and cutters, ensuring your metal fabrication process is seamless.

-

Precision and Performance: High-quality fabrication tools lead to precise cuts, strong welds, and better overall project results.

-

Durability: Our tools are built to last, so you can rely on them for years to come.

-

Versatility: Whether you're welding tubing, assembling metal structures, or working with complex processes, our metal fabrication tools adapt to your needs.

6 Top Essential Welding Tools for Fabrication Work

Get ready for top-quality building work with these 6 must-have welding tools! This list gives you all you need, from safety gear to advanced machines, for great welding jobs.

1. Welding Helmet

A welding helmet is crucial for protecting your eyes and face from bright light and sparks. Choose a helmet with a comfortable fit and modern features like auto-darkening lenses.

Read our guide for choosing the right welding helmet.

2. Welding Gloves

Welding gloves Keep your hands safe from heat, sparks, and sharp edges with durable welding gloves. These gloves are essential for both safety and comfort during your metal fabrication.

3. Welding Machine

Your welding Machine is the most critical tool in your setup. Whether you're using a MIG, TIG, or Stick welder, ArcCaptain offers a wide range of welding machines to suit every project and process.

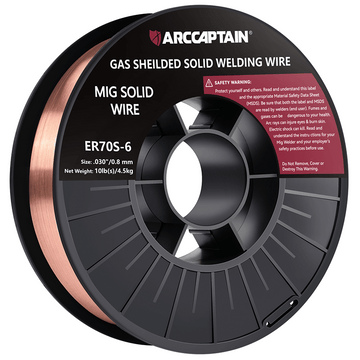

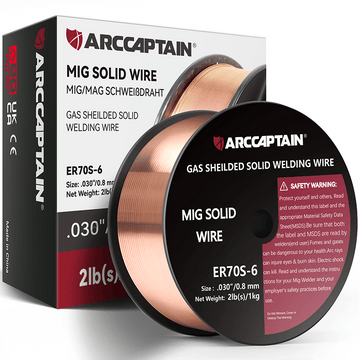

4. Electrodes or Welding Wire

Welding wire or electrodes are used to join metal pieces. We carry a variety of welding wire types, including MIG and flux-cored, to fit different fabrication processes.

Learn more about welding wire in this article: Different Types of MIG Welding Wire

5. Angle Grinder

An angle grinder is a versatile tool used for cutting, grinding, and polishing metal. It’s a staple for any metal fabrication project.

6. Plasma Cutters

Plasma Cuttersuse high-temperature ionized gas to slice through metal with precision. These powerful tools are perfect for cutting tubing and other conductive materials.

Each of these fabrication tools plays an essential role in improving your project’s efficiency, precision, and safety. With the right setup, you can tackle any fabrication project that comes your way.

Finding the Right Tools for Your Projects

At ArcCaptain, we understand that every project is unique. Whether you’re working with tubing, sheet metal, or heavy structural materials, having the right metal fabrication tools is key to success. Our selection of fabrication tools caters to all skill levels and project requirements, ensuring you always have the right tool for the job.

-

Choose Your Tools: We offer a wide range of tools, from cutting and welding to finishing. Pick the ones that best fit your project’s scale and complexity.

-

Budget-Friendly Options: Look out for our sale prices and bundle save 10 offers to get the most value out of your fabrication tool investments.

Why Choose ArcCaptain for Your Metal Fabrication Needs?

-

Expert Advice: Our team of experts is available to help you select the right fabrication tools for your project. Whether you’re building something small or large, we’ve got you covered.

-

Quality and Reliability: We pride ourselves on offering durable, high-quality tools that stand up to the demands of metal fabrication.

-

Quick Shipping: Ready to start your project? We offer fast shipping to ensure you get your tools quickly, with select items available for free shipping.

Step up your metalworking game with ArcCaptain’s selection of metal fabrication tools. From beginners to professionals, we provide the tools you need to achieve excellent results in every project. Check our regular prices and don’t forget to take advantage of our sale prices to save even more. Add your tools to the cart today and experience the difference quality fabrication tools can make!

Frequently Asked Questions

What Are the Three 3 Types of Metal Fabrication?

The three main types of metal fabrication are cutting, bending, and assembling. Cutting involves slicing through metal, bending reshapes the material, and assembling combines pieces, often through welding. Each step requires specific fabrication tools.

Is Welding a Type of Fabrication?

Yes, welding is an essential part of metal fabrication. It’s used to assemble or join metal pieces together to create structures or products. Many fabricators use MIG, TIG, and Stick welding in their fabrication process.

Is a Fabricator a Welder?

While a fabricator may use welding, the roles are distinct. A fabricator shapes and assembles metal into a final product, while a welder focuses solely on joining metal pieces using various welding techniques. In many cases, fabricators need to know how to weld, but their skill set goes beyond welding.

What Welding is Used in Steel Fabrication?

The most common welding methods in steel fabrication are MIG, TIG, and Stick welding. MIG welding is widely used for its speed and versatility, while TIG welding offers greater precision, especially on thin metal. Stick welding is ideal for outdoor or rough conditions.